Plenty of people have increased revenue and reduced costs with ERP and still managed to run their business into the ground. Why? Because they failed to hit on the right combination of business processes to reach their actual objective – increased profit.

It’s well documented that relying on raising prices or reducing resources to lower costs comes with the inherent risk of losing customers, sacrificing quality, and weakening the organization. Although we'd all like to think that implementing an ERP solution solves all those problems, there’s still one missing element: people.

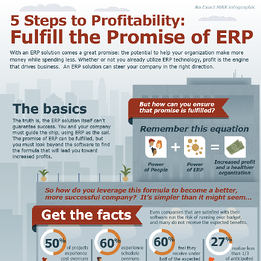

When the power of people is combined with the power of ERP you have a complete set of tools in your arsenal to put you on the path to increased profits and a healthier organization. The key is to take action. Here are five actions to consider.

Click on the image to the right to view the full infographic.

Manage and measure change

Instead of launching a great idea, execute ideas from an actionable plan. This avoids wasting valuable resources on educated guesses and ending up with great ideas that go nowhere.

Despite what you may be thinking, it’s not difficult to find a standard methodology to use for developing your plan. The Project Management Institute is one of the best known sources for providing tools to successfully implement new ideas. You don’t necessarily need to have certified project managers. Just use the basic framework of one of the proven methodologies. This will drive down costs by ensuring your people can be productive and efficient when tasked to implement plans. To minimize disruption to your business, don’t forget to include in your plan any necessary changes in your existing ERP processes. Also be sure to establish benchmarks that can be uded to measure the impact on your business.

Streamline the critical path

Analyze the impacts of automating your manual processes. Barcoding and data collection systems are readily available for most ERP systems. By automating your processes and speeding up the paperwork, you can expedite the completion of product and reduce errors. This will drive down your time to market without sacrificing quality. There are also mobility, web-based tools to speed up the process of getting from quote to sale with distributors or remote sales teams.

Lead evolution not revolution

Lead evolution – not revolution – with a technology roadmap for slow and steady change. Periodic, major leaps in your infrastructure and ERP systems can cause costly disruptions and take sizable chunks out of your budget when done all at once. Smooth out the cost curve with a slow and steady approach towards the goal of a paperless system and/or staying on supported software. Have a team review the new feature/function/fix lists and have a plan to update your processes to incorporate relevant functions made available by updates to your ERP system.

Too often businesses continue to keep outdated processes in place for years and fail to harness available technology that could fuel growth for their business. A common result is they become dependent upon one or two key people. A healthy organization is one that continues to evolve and functions as a unit. It has visible processes allowing for backups and adoption of new ideas. A healthy business will resist stagnation and will not crumble in the face of change.

Create a listening organization

Implement customer, vendor, and employee experience feedback loops that feed into regularly monitored key performance indicators. Financial indicators are important but they can only tell you what already went right or wrong. People can tell you what’s going right or wrong with time to take action. It cannot be assumed you’ll get this information from department heads and meetings that gather opinions not grounded in supporting data. Assumptions and relying on past experience has caused many a mistake and missed opportunity. There is no need to hope for the best when your ERP system is designed to give you critical data points to support logical decision making. If your meetings are not built around KPIs as the basis for actionable plans, then you need a project to identify them and get those reports and dashboards in place.

Create a learning organization

Conduct Lessons Learned sessions based on “What could we have done better” not “What did we do wrong.” These should be done at the end of a project or on specific business milestone like year-end or end of busy season. Lessons Learned should be incorporated into existing ERP processes or may require an actionable project plan that can be measured and managed (see step 3).

When we work companies implementing our software, we see a new energy that gets harnessed and fed into ERP, but it doesn’t stop there. That energy, combined with ERP, will help you increase your company’s profit and ensure that your organization is healthier overall.

Know that these steps will lead you to take confidant action in adapting to ever-changing conditions, maintaining the health of your business, fueling growth and increasing profitability.